Cessation

Pursuant to the Frigg treaty, the British and Norwegian governments agreed that the disposal of all the installations on the field should be outlined in one cessation plan. This would also take account of each nation’s legal requirements, and accord with the principles which had underlain the operation of Frigg throughout.

This comprehensive decision-making process was intended to ensure the participation of all interested parties, both in Norway and the United Kingdom. An extensive process of consultation involved obtaining comments from both fisheries and environmental organisations and government authorities. The plans involved to leave the concrete bases of the platforms, therefore the signatories of the OSPAR-convention also had to be consulted, in accordance to OSPAR decision 98/3 [REMOVE]Fotnote: Christian Hansen: From a Chinese butterfly to nails, 2006..

A cessation plan for Frigg was submitted to the UK and Norwegian authorities in November 2001, and was on public hearing for three months. The principles for shutting down and removal had to be approved by both governments. During the process, weight was given to maintaining close contact with and securing comments from various stakeholders. These included environmental and fishing organisations as well as government agencies. The process was pursued in such detail to avoid the kind of confrontations associated with Brent Spar.

In 2003 it was decided that the platform MCP-01 in british sector should be taken out of use. The MCP-01 had a concrete base, and was part of the pipeline system to the gas terminal at St Fergus in Scotland. The operator Total E&P UK in Aberdeen decided that the removal of the topsides at MCP-01 should be a part of the Frigg cessation project, with Total E&P Norge in charge. In 1004 and 2005 the pipelines were laid in a bypass around MCP-01, as they would still be in use to transport gas from other fields.

The Norwegian Frigg pipeline was tied back to the Heimdal gas hub, and became part of the Vesterled transport system. For its part, the UK pipeline was tied back to several fields on the British side. As a result, the pipelines from Frigg to St Fergus were not included in the cessation and removal work.

During the process, the possible use of Frigg installations as a hub for gas transport and processing was assessed. This requirement disappeared when Heimdal was converted for that purpose.

Fjerning av installasjoner

Fjerning av installasjonerBefore a decision was taken on removing the installations, detailed studies were prepared on the environmental consequences. These included a number of proposals for using the GBSs – such as artificial fish reefs, foundations for wind turbines or carbon-free gas-fired power stations, and foundations for a bridge across the Gands Fjord near Stavanger. Many of these options involved great technical uncertainties, and none were regarded as financially viable.

Possibilities for removing the concrete structures were also studied. Rimoval and disposal onshore was the first alternative that was studied. Under the 1998 Ospar convention, these could be left in situ if they were secured and satisfactorily marked. The GBSs had not been designed with an eye to their removal, and proved difficult to shift. Other alternatives of disposal were appraised as described in OSPAR decision 98/3. An accident while they were being refloated could have major consequences. The GBSs might collide and sink to the seabed in a damaged condition. Such a scenario would present a major safety hazard and high additional costs.

Cutting off the tops of the concrete shafts 55 metres below the sea surface was also considered. That would satisfy the IMO’s requirements, but was assessed to be even riskier than removal.

It was finally decided to abandon the GBSs and drill cuttings on the seabed. The latter are drilling residues which accumulate around a well. Surveys showed that the layer of cuttings on Frigg was thin and covered by sand[REMOVE]Fotnote: Drill cuttings. An important issue in the environmental debate. Frigg Area Cessation News no 2 2000.. They derive from the topmost level of a well and contain no petroleum residues or polluting chemicals.

Fjerning av installasjoner

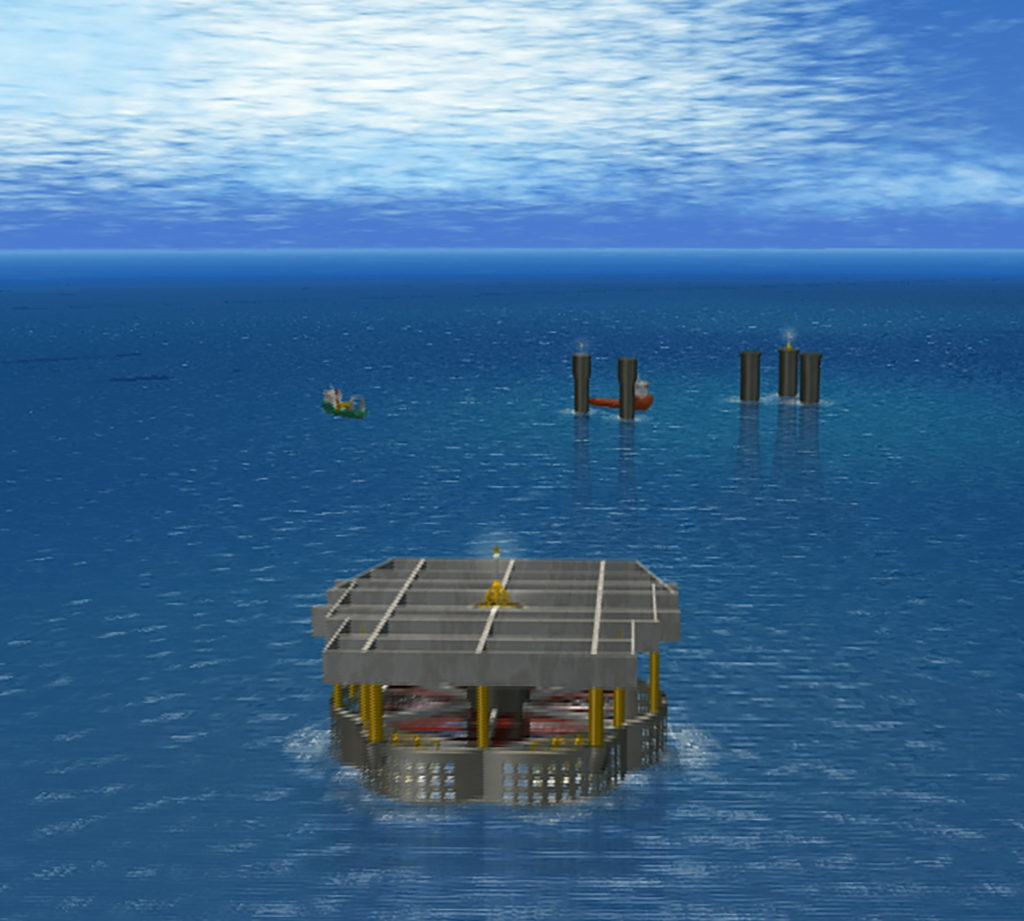

Fjerning av installasjonerSteel jackets and all the platform topsides were to be removed, along with pipelines and cables on the seabed. By 2012, only the GBSs for the TP1, TCP2 and CDP1 platforms at Frigg will be showing above the water. They will be marked by beacons to prevent vessels colliding with them.

The goal is that 98 per cent of everything taken to land will be recycled.

Total E&P Norge awarded Stavanger-based Aker Kvaerner Offshore Partner AS a contract in October 2004 to serve as main contractor for the removal project and for disposal on land[REMOVE]Fotnote: Press release, Aker Kvaerner Offshore Partner: Aker Kvaerner to remove platforms on the Frigg field, 26 October 2004.. The project included the installation at the Frigg field and the topsides of MCP-01. This job was worth NOK 3 billion, and a consortium comprising Aker Kvaerner Offshore Partner, Saipem, Shetland Decommissioning Company and Aker Stord were given responsibility for the work. Aker is to remove 85 000 tonnes of steel from 2005-08, of which 20 000 will be shipped to Shetland. The remaining 65 000 tonnes is being sent to Aker Stord for breaking up and recycling.

All pipelines were cleaned and every well plugged during 2004, and the platforms were also cleaned and readied for disassembly.

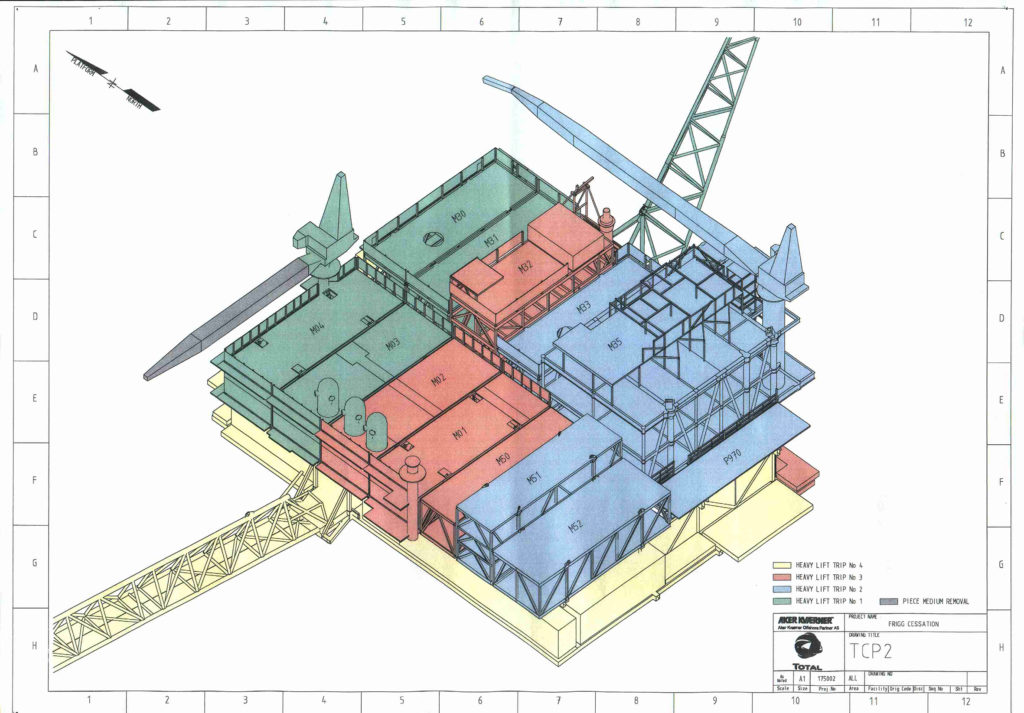

Removal work on Frigg got fully under way in August 2005, and is expected to continue until 2010. This work is being carried out module by module in the opposite sequence to their installation. The Saipem 7000 crane barge, which can lift up to 14 000 tonnes with its two cranes, has been used for the heaviest lifts[REMOVE]Fotnote: The Work Begins. Offshore Removal and Onshore Disposal. Frigg Area Cessation News no 8, May 2005.. After being stowed on this vessel’s deck, the modules were transported to Aker Stord.

The process involved heavy module lifts combined with cutting the platforms up into smaller sections for transport in open containers to land. Saipem 7000 has worked on Frigg for a number of months, with more than 100 heavy lifts.

Plans call for the DP2 and QP jackets to be removed with the aid of buoyancy tanks. The structures will be raised gradually as the tanks are deballasted, and then towed to Stord for disassembly.

Because of earlier damage, the DP1 jacket cannot be removed in the same way as the others. The upper part of the DP1 jacket has already been cut off by a remotely operated vehicle (ROV) and removed by Saipem 7000[REMOVE]Fotnote: Patrick Decosemaeker, Total: Prinsipper for vurderinger og problemstillinger knyttet til fjerning av Frigg, Presentation to the Petroleum Safety Authority Norway, 23 August 2006.. This work was coordinated by DeepOcean in cooperation with Norse Cutting & Abandonment AS. Using ROVs eliminated the need for diver assistance[REMOVE]Fotnote: DeepOcean Goes Diverless, Scandinavian Oil-Gas Magazine no 1/2 2006.. Such vehicles have also been deployed for other cutting work on the various jacket legs. More than 1 200 such operations have been performed with the aid of ROVs. One of these units was also used to remove steel structures from the exterior of the TP1 and TCP2 GBSs[REMOVE]Fotnote: Grutle, Magnus: External steel removal for Frigg field platform, Scandinavian Oil-Gas Magazine no 1/2, 2007.

The heaviest lifts relate to TCP2 and DP1, with M35 as the heaviest module at 3 125 tonnes[REMOVE]Fotnote: Lifting Campaign in 2005. Frigg Area Cessation News no 9, July 2006.. Weighing some 9 000 tonnes, the module support frame for TCP2 is due to be raised in a single lift and shipped to Shetland. The DP1 topside weighed 3 700 tonnes.

To help coordinate this work, a dedicated website was established with information on the various installations. This Cessation Web site provides the various players with access to a digital library and has proved flexible and time-saving. Required information is posted for collective use within the project.