Frigg platform accident – the DP1 story

McDermott was responsible for design and management, and the structure was to be fabricated at Union Industrielle et d’Enterprises at Cherbourg in France. Certification responsibility rested with classification society Det Norske Veritas and Oceanic was in charge of transport and installation on the field. Work was completed on schedule in 1974, and the jacket was towed to Stavanger in late June 1974.

Forliset av DP1, feltet,

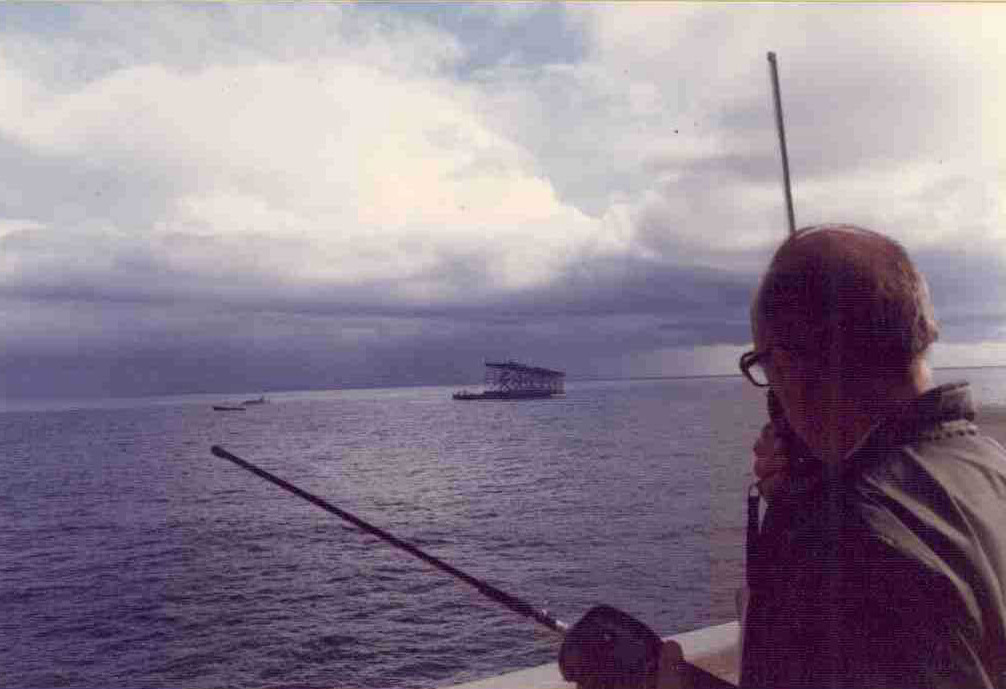

Forliset av DP1, feltet,But the difficulties began when the jacket was to be taken out to the field. The first problem arose with the DB 22 Oceanic crane vessel, which was due to lift the structure into position on Frigg. This ship suffered a failure during an assignment on Ekofisk a couple of weeks earlier. A replacement accordingly had to be found.

The market was reasonably tight, but Total had a vessel – the ETPM 1601 – which was to be used for pipelines. This was straightforwardly transferred to Elf for use as a crane ship. The barge to carry the jacket from Stavanger to the field was due to be ready and leave the yard in Hamburg at the end of June 1974, but did not actually set out until early September. Poor weather meant that the jacket was not towed out to the By Fjord off Stavanger until 9 October.

Forliset av DP1, feltet,

Forliset av DP1, feltet,The launch of the 6 700-tonne jacket was initiated on the morning of 14 October on the NCS, 1 500 metres from the boundary and 1 600 metres from the site originally planned on the UKCS. Plans called for the structure to be raised first into a vertical position and then sunk until its feet were five-six metres above the seabed, before being manoeuvred into its exact location.

After the jacket had entered the water, however, one of its buoyancy tanks collapsed and the structure began to sink. The rising water pressure also ruptured the remaining buoyancy tanks and the jacket hit the seabed.

Two of its legs were bent by the force of the collision, and the whole structure sank in 107 metres of water. Errors had been made in calculating the strength of the buoyancy elements intended to ensure that the jacket could be elevated from horizontal to vertical in a controlled way. As a result, the steel in the tank walls was too thin.

Forliset av DP1, feltet,

Forliset av DP1, feltet,A extensive rescue operation was initiated, with a series of attempts to salvage the wrecked structure. Two days after the accident, the ETPM 1601 crane ship lifted the jacket a couple of metres off the seabed, but bad weather put a halt to the operation.

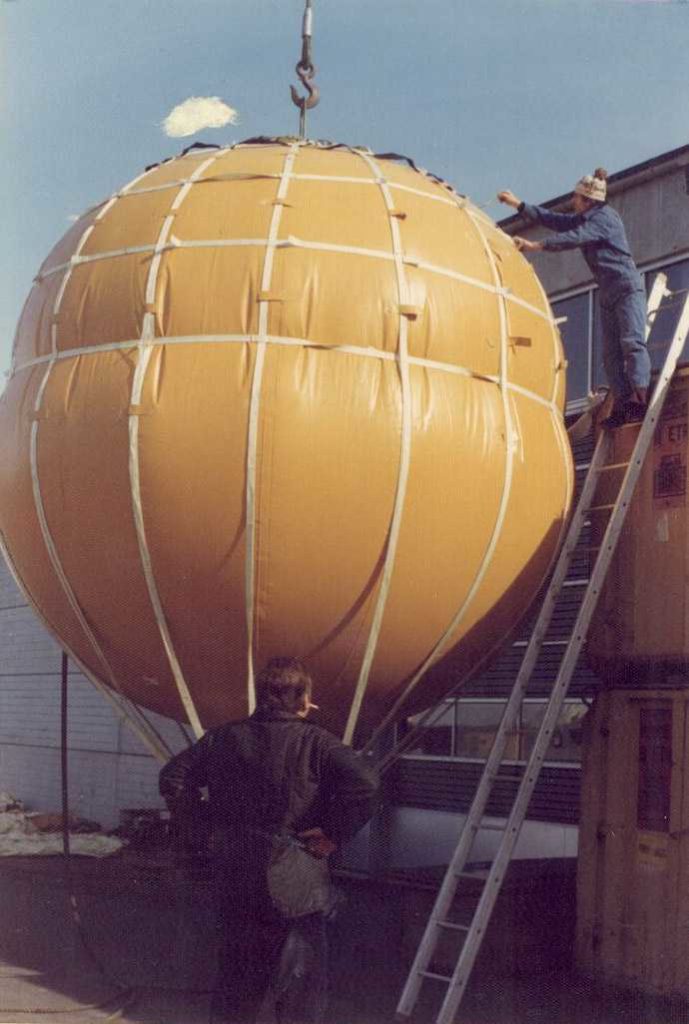

Steadily worsening conditions meant that all further work had to be postponed until the spring of 1975. The next lifting attempt involved attaching 30 large plastic spheres to the wreck so that their buoyancy would provide the necessary lift while ETPM 1601 moved the structure to the right position. Testing of the spheres revealed material weaknesses, however, and the project was abandoned.

The jacket was again raised a little from the seabed in July 1975 and moved closer to its original site, but it eventually became clear that the structure had suffered additional damage from the winter storms and could not be rescued. It was abandoned in a depth of 107 metres, with only a metre showing above the surface.

Elf now needed a new platform support. Total had a concrete gravity base structure (GBS) under construction at Åndalsnes, which was intended for manifold platform 1 (MP1). This unit was converted for drilling and replaced the lost DP1 jacket. It was renamed the concrete drilling platform 1 (CDP1). Total had to build a replacement GBS.

No space was available in the dry docks in Stavanger, Åndalsnes, Stord or Scotland. However, Sweden’s Skånska Cementgjuteriet (later Skanska) had space in a new dock outside Strömstad. So the GBS for the manifold compression platform (MCP-01), intended to maintain transport pressure in the Frigg gas on its way to St Fergus, was built there.

Forliset av DP1, feltet,

Forliset av DP1, feltet,The loss of the DP1 jacket hit the financial estimates for the Frigg development, with both budget and timetable overruns. The price tag for the project rose from NOK 1.3 billion to about NOK 5 billion from the spring of 1972 to the summer of 1974.

This accident also resulted in heavy pressure from the owners, financial institutions, the BGC and the insurance companies. Elf had to take action, and a restructuring of the development organisation for the field was instituted. The operator wanted better control of the project, and not least of the contractors. Jean Curutchet was put in charge.

Read more:

1975: Elf appoints Jean Curutchet to head Frigg

1975: Dedicated public affairs personnel

Sources:

Lie, E. (2005). Oljerikdommer og internasjonal ekspansjon : Hydro 1977-2005 (Vol. B. 3). Oslo: Pax.

Noroil, November 1974 and May 1975